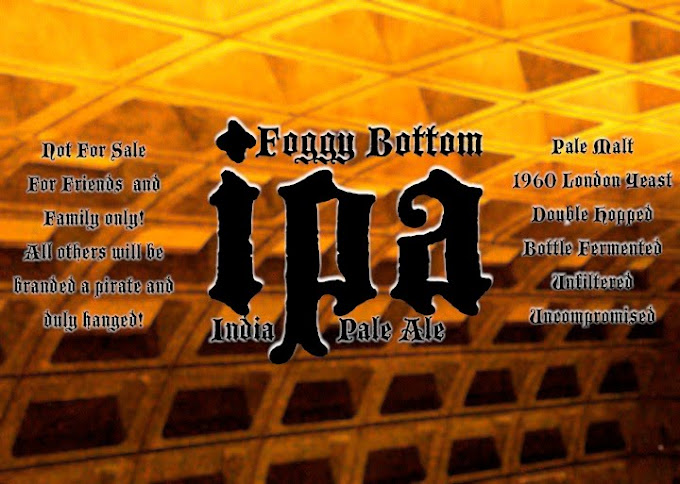

A few weeks ago I made a batch of IPA. The weather was pretty cool, I think it was our first cool front of the fall. It was a random recipe I simply made up, but it turned out amazing. I believe part of the reason was that it was cool. The other thing was that I had a spot available in my beer fridge to help get the temperature down to the 60's within a day of pitching, and the 3rd thing was that it was a 5 gallon batch (those 15 gallon batches can be a pain to cool down in time to prevent oxidation of beta acids) and finally the 4th thing was the use of a hand made wort chiller. I really think oxidation has been one of the biggest nuisances in brewing. I would have expected sanitation issues or something else, but so far I think the main thing that has messed up the flavor has been oxidation. Anyway, after conditioning this IPA came out perfect to my taste. It was a little on the dry-hop side before conditioning, not totally balanced, but Americans don't really want a balanced IPA anyways. That's what makes us so badass. We can just defy traditional brewing methods in the name of innovation or novelty and come up with some really great recipes.

Just a few days ago (Nov 12) I brewed a dark brew, probably somewhere in between a porter and imperial stout. It's the same hops schedule as the IPA: Magnum, Nugget, Cascades but a much darker malt profile. I believe it was 12 lbs 2-row, 1 lb German de-husked Caraffe II, 3/4 lb Belgian Biscuit, and 3/4 lb British Dark Crystal. It sure came out dark looking, with a rich, sweet smell. I'm sure the bitterness of the bittering hops will be noticeable. I'm planning on dry hopping it with Willamette and possibly a half ounce or so of Cascade hops.

Though patience is a virtue, I'm not sure it's my strong point. During the lagering of the Dortmunder Lager, which has taken over 3 months, I personally went through more than 4 gallons and gave away almost as much. There was about 6 gallons of finished, fully fermented and dry hopped dortmunder lager, and the stuff that survives to this day is fantastic, though it's less than a case. Also the "Darth Porter" has been bottled. It has been aging since march, and I just re-bottled it to smaller bottles, and dry hopped about half of it. It has a pretty high alcohol content. I would guess around 9%, though I didn't measure the gravity on this one. Should be great around Thanksgiving and Christmas.

Finally the last beer I have sitting in the brew closet is a frankenstein of ales. Many of the previous batches we made ended up getting oxidized in the extreme heat of the summer. The brew closet was air conditioned better than the house, but not as well insulated. All it takes to oxidize your beer is getting it to sit at 86 for a few days. Anyways, since I was incredibly unsatisfied with these beers, I uncapped a ton of them and dumped them in a carboy with some sugar to cause another fermentation. These were at least 3 different kinds of beers, maybe 5. After fermentation, I racked it off the new trub and dry hopped it with Cascades. I don't know if it was the yeast, eating up all the defective flavors or if it was the antioxidants from the hops, maybe a combination of the two, but the oxidized gross flavor is gone. Not covered up, but disappeared. It's not the best beer compared to the current lineup, but it's good. I'd say it is better than what it was even before the oxidization. It's kind of a light amber ale, a little hoppy but balanced. Probably 6%. Definitely a learning experience.