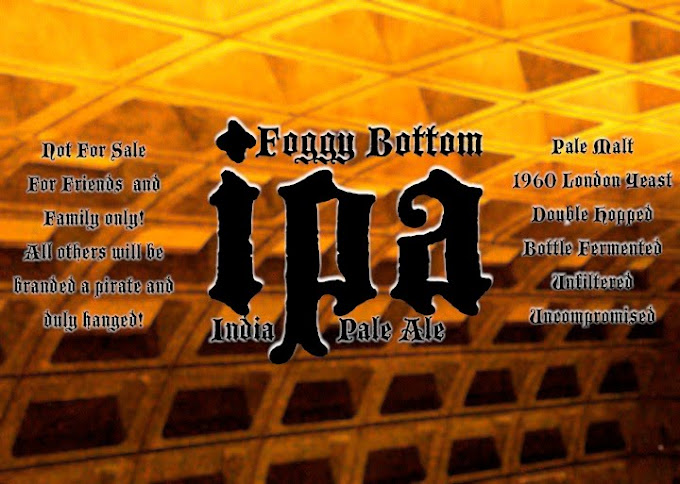

A few weeks ago I made a batch of IPA. The weather was pretty cool, I think it was our first cool front of the fall. It was a random recipe I simply made up, but it turned out amazing. I believe part of the reason was that it was cool. The other thing was that I had a spot available in my beer fridge to help get the temperature down to the 60's within a day of pitching, and the 3rd thing was that it was a 5 gallon batch (those 15 gallon batches can be a pain to cool down in time to prevent oxidation of beta acids) and finally the 4th thing was the use of a hand made wort chiller. I really think oxidation has been one of the biggest nuisances in brewing. I would have expected sanitation issues or something else, but so far I think the main thing that has messed up the flavor has been oxidation. Anyway, after conditioning this IPA came out perfect to my taste. It was a little on the dry-hop side before conditioning, not totally balanced, but Americans don't really want a balanced IPA anyways. That's what makes us so badass. We can just defy traditional brewing methods in the name of innovation or novelty and come up with some really great recipes.

Just a few days ago (Nov 12) I brewed a dark brew, probably somewhere in between a porter and imperial stout. It's the same hops schedule as the IPA: Magnum, Nugget, Cascades but a much darker malt profile. I believe it was 12 lbs 2-row, 1 lb German de-husked Caraffe II, 3/4 lb Belgian Biscuit, and 3/4 lb British Dark Crystal. It sure came out dark looking, with a rich, sweet smell. I'm sure the bitterness of the bittering hops will be noticeable. I'm planning on dry hopping it with Willamette and possibly a half ounce or so of Cascade hops.

Though patience is a virtue, I'm not sure it's my strong point. During the lagering of the Dortmunder Lager, which has taken over 3 months, I personally went through more than 4 gallons and gave away almost as much. There was about 6 gallons of finished, fully fermented and dry hopped dortmunder lager, and the stuff that survives to this day is fantastic, though it's less than a case. Also the "Darth Porter" has been bottled. It has been aging since march, and I just re-bottled it to smaller bottles, and dry hopped about half of it. It has a pretty high alcohol content. I would guess around 9%, though I didn't measure the gravity on this one. Should be great around Thanksgiving and Christmas.

Finally the last beer I have sitting in the brew closet is a frankenstein of ales. Many of the previous batches we made ended up getting oxidized in the extreme heat of the summer. The brew closet was air conditioned better than the house, but not as well insulated. All it takes to oxidize your beer is getting it to sit at 86 for a few days. Anyways, since I was incredibly unsatisfied with these beers, I uncapped a ton of them and dumped them in a carboy with some sugar to cause another fermentation. These were at least 3 different kinds of beers, maybe 5. After fermentation, I racked it off the new trub and dry hopped it with Cascades. I don't know if it was the yeast, eating up all the defective flavors or if it was the antioxidants from the hops, maybe a combination of the two, but the oxidized gross flavor is gone. Not covered up, but disappeared. It's not the best beer compared to the current lineup, but it's good. I'd say it is better than what it was even before the oxidization. It's kind of a light amber ale, a little hoppy but balanced. Probably 6%. Definitely a learning experience.

No I'm not starting a brewing company. I'm just a hobbyist. I brew in 5-gallon batches, every couple of weeks. I drink and brew almost exlusively Ale. This is because of the flavor. Flavor, even extreme bitterness, is a good thing in beer. Lager also happens to be much more difficult to brew, so Ale it is for now.

Sunday, November 13, 2011

Friday, July 8, 2011

Microbrewery On The Horizon?

didn't ever expect to even consider doing this, but a few friends who Mike and I have been sharing beers with have been talking about starting a micro-brewery and having Mike and I as the master-brewers. That would be really awesome in many ways! 1: doesn't need to be explained - opening a micro-brewery is just freakin awesome! 2: I've always had a dreams of entrepreneurship and if this thing takes off it would be a dream come true. 3: It could really work out well for us, as a way for me to bring in some income and still stay at home most of the time. 4: It could really take off and make mucho dinero because I believe it's the right place and the right time! The craft brewing industry is booming and it has yet to take Houston, and it's just starting here. It could be a crazy ride.

So far the accomplices are Mike Mike Mike and Josh.

There's got to be some kind of cool company name we could make of that. Something like 3Mikes Brewing

So far the accomplices are Mike Mike Mike and Josh.

There's got to be some kind of cool company name we could make of that. Something like 3Mikes Brewing

Monday, May 2, 2011

Where to Start?

I don't think I have the time to write about everything that has happened in my microcosmos of brewing since the last post, but I'll give a tiny update that covers a lot and then maybe later I'll find time to fill in more.

There were a handful of brews which I can't remember right now, I'll have to go read the labels and see if I managed to record them on my brewing log, but I believe I brewed a stout or 2 and something else that was pale with medium hoppiness. Then came the 3 week brewathon with Mike. We went to the homebrew shop and Mike was determined to fill every possible fermenter we had. We bought ingredients for about 3 pale ales (made up recipes), 1 Elissa Clone, 1 Sierra Nevada Celebration Ale clone, 1 Stone Darth Porter clone (oaked), 1 Rogue Dead Guy Ale clone (my personal favorite), a made up German Imperial Stout recipe (oaked), 1 Stone Ruination IPA clone (oaked) and 2 other brews, which I made from ingredients that I had bought right before the huge trip to the brew store. I believe one was a hoppy Pale Ale and the other was a red ale.

So far we bottled the Sierra Navada clone, a pale ale with Czech hops, a pale ale with Cascades hops, and another pale ale with a variety of hops, and the Dead Guy. The pale ales generally are pretty mild - we intended those to be people pleasers, the Celebration Ale was pretty hoppy, very good but a little overcarbonated, the Dead Guy came out great. It's got such a great malty aroma and medium-strong hoppiness. I don't think it tastes like real Dead Guy buy it's amazing. 5 gallons of the 15 of the mixed hop pale ale we set aside and I added a ton of dry hops to it, so it should be very aromatic with a good IPA hoppiness. I will be bottling that right now - like when I finish typing.

Needless to say my tiny beer fridge is loaded. Believe it or not less than 10% of what's in there is from our brewathon. If anyone wants to come over and have a beer - feel free.

There were a handful of brews which I can't remember right now, I'll have to go read the labels and see if I managed to record them on my brewing log, but I believe I brewed a stout or 2 and something else that was pale with medium hoppiness. Then came the 3 week brewathon with Mike. We went to the homebrew shop and Mike was determined to fill every possible fermenter we had. We bought ingredients for about 3 pale ales (made up recipes), 1 Elissa Clone, 1 Sierra Nevada Celebration Ale clone, 1 Stone Darth Porter clone (oaked), 1 Rogue Dead Guy Ale clone (my personal favorite), a made up German Imperial Stout recipe (oaked), 1 Stone Ruination IPA clone (oaked) and 2 other brews, which I made from ingredients that I had bought right before the huge trip to the brew store. I believe one was a hoppy Pale Ale and the other was a red ale.

So far we bottled the Sierra Navada clone, a pale ale with Czech hops, a pale ale with Cascades hops, and another pale ale with a variety of hops, and the Dead Guy. The pale ales generally are pretty mild - we intended those to be people pleasers, the Celebration Ale was pretty hoppy, very good but a little overcarbonated, the Dead Guy came out great. It's got such a great malty aroma and medium-strong hoppiness. I don't think it tastes like real Dead Guy buy it's amazing. 5 gallons of the 15 of the mixed hop pale ale we set aside and I added a ton of dry hops to it, so it should be very aromatic with a good IPA hoppiness. I will be bottling that right now - like when I finish typing.

Needless to say my tiny beer fridge is loaded. Believe it or not less than 10% of what's in there is from our brewathon. If anyone wants to come over and have a beer - feel free.

Monday, November 8, 2010

1 Gallon Glass bottles!

Whole Foods is selling natural apple juice in 1 gallon glass jugs. It's really good apple juice and the glass bottles are just like baby carboys. The homebrew shop has bungs and airlocks for cheap, and I've been curious about brewing different kinds of ale in small batches so the glass bottles are perfect. It's a lot easier to brew one gallon at a time for obvious reasons. What's great is that I can pour the hot wort right into the bottle (I preheat the bottle with hot water in the sink first so the glass doesn't break) and then cool it inside the glass. It really reduces the risk of contamination that could normally happen while cooling in the pot or during siphoning. And obviously it's much easier to cool 1 gallon than 5. The darker one on the left is a Christmas stout and the lighter one on the right is cider. I just poured a glass of juice, then shook the juice to aerate it and pitched the yeast and threw on the airlock. Talk about easy. It started bubbling away within 24 hrs and it's been going for about 5 days now. I have no idea how much sugar (fructose) is in there or how long it will take to finish fermenting. If it comes out good, I think I'll be doing it all winter.

Whole Foods is selling natural apple juice in 1 gallon glass jugs. It's really good apple juice and the glass bottles are just like baby carboys. The homebrew shop has bungs and airlocks for cheap, and I've been curious about brewing different kinds of ale in small batches so the glass bottles are perfect. It's a lot easier to brew one gallon at a time for obvious reasons. What's great is that I can pour the hot wort right into the bottle (I preheat the bottle with hot water in the sink first so the glass doesn't break) and then cool it inside the glass. It really reduces the risk of contamination that could normally happen while cooling in the pot or during siphoning. And obviously it's much easier to cool 1 gallon than 5. The darker one on the left is a Christmas stout and the lighter one on the right is cider. I just poured a glass of juice, then shook the juice to aerate it and pitched the yeast and threw on the airlock. Talk about easy. It started bubbling away within 24 hrs and it's been going for about 5 days now. I have no idea how much sugar (fructose) is in there or how long it will take to finish fermenting. If it comes out good, I think I'll be doing it all winter.

Saturday, October 30, 2010

Diffusing Beer Bombs

It was an interesting educational experience today. I had bottled some stout that I had recently brewed because I had the time, and there hadn't been any apparent activity in the fermenter for a few days. I normally sample the beer at various points of conditioning to see how carbonated it is, etc.. and just 2 days after bottling it was fully carbonated. Obviously the beer was going to get way too carbonated for safety, so I put all the beers in the fridge to halt fermentation until I figured out what to do next, (and as I mentioned before, I was nervous about bottles blowing up and leaving a black mess and glass shrapnel in the closet. So I asked Callie if I could borrow her welding helmet and leather gloves so that I could open the bottles without risking putting glass in my body. The fridge did a great job of halting fermentation. If anything, the bottles seemed less pressurized than before. The swing-tops that I left in the closet were dangerously pressurized after just a couple days though and they seemed like they were really on the brink of exploding. But it was as easy as popping the tops a few times to vent the pressure. Just so you know, the reason the beer tricked me into thinking it was ready to be bottled was that though there was still a lot of fermentable sugars left in the beer, the oxygen had been completely attenuated, so the yeast growth had simply slowed down to one 20th or so of what it had been. But it was still going, just very slowly. The reason that the oxygen was depleted so soon compared to the sugars this time was because it was such a malty beer (I added 4 pounds on top of the normal 5 pounds of amber liquid malt that would normally make an amber ale similar to a Shiner Bock).

What did we learn? Let your beer have lots and lots of time in the fermenter even if it seems like the activity stopped, especially if it's a big one.

Thursday, October 28, 2010

Ok this is my stout that I just brewed. I have never even read a recipe for a stout, but on a whim I got some dark malt when I was at the homebrew shop. I used 5lbs amber liquid malt, which on its own would make something like Shiner Bock, then 2lbs Crystal Dark malt and 2lbs Chocolate Malt Pearls (almost the darkest malt they had - with the husk removed). I used 1lb liquid light for bottle conditioning instead of dextrose. 2 days after bottling, I tried it to see how it tasted before the liquid light was fully fermented, but it seemed like it was fully carbonated. Out of fear of exploding bottles, I put the rest of the batch in the fridge to slow the fermentation. I've never exploded bottles before, but this stuff is sooo dark - darker than any stout you have ever seen - darker than espresso - I didn't want to stain the closet walls and carpet if the bottles exploded. The beer in the picture is a 1 liter - it was actually most of the stout I

Ok this is my stout that I just brewed. I have never even read a recipe for a stout, but on a whim I got some dark malt when I was at the homebrew shop. I used 5lbs amber liquid malt, which on its own would make something like Shiner Bock, then 2lbs Crystal Dark malt and 2lbs Chocolate Malt Pearls (almost the darkest malt they had - with the husk removed). I used 1lb liquid light for bottle conditioning instead of dextrose. 2 days after bottling, I tried it to see how it tasted before the liquid light was fully fermented, but it seemed like it was fully carbonated. Out of fear of exploding bottles, I put the rest of the batch in the fridge to slow the fermentation. I've never exploded bottles before, but this stuff is sooo dark - darker than any stout you have ever seen - darker than espresso - I didn't want to stain the closet walls and carpet if the bottles exploded. The beer in the picture is a 1 liter - it was actually most of the stout I opened mixed with an IPA. It wasn't bitter at all (as far as my homebrew goes). It's crazy how the smooth creamy body of the British Chocolate Malt Pearls smooths out the bitterness of hops and tannins. And it's like eating a meal. I was just enjoying it without giving it too much thought, and it took me 2 hours to finish it (24 ounces total). This picture to the right is after an hour. I don't drink a lot of stout so I didn't realize how filling it can be. Also I pulled about a 6-pack worth of the stout aside and I'm using a food-quality small plastic bucket to Franken-brew a killer BIG and hoppy version of it (inspired by Stone's Sublimely Self-righteous Ale - only twice as dark and meaty).

opened mixed with an IPA. It wasn't bitter at all (as far as my homebrew goes). It's crazy how the smooth creamy body of the British Chocolate Malt Pearls smooths out the bitterness of hops and tannins. And it's like eating a meal. I was just enjoying it without giving it too much thought, and it took me 2 hours to finish it (24 ounces total). This picture to the right is after an hour. I don't drink a lot of stout so I didn't realize how filling it can be. Also I pulled about a 6-pack worth of the stout aside and I'm using a food-quality small plastic bucket to Franken-brew a killer BIG and hoppy version of it (inspired by Stone's Sublimely Self-righteous Ale - only twice as dark and meaty).

Tuesday, October 26, 2010

The brewing has been crazy fun lately. Here's the last week:

90 minute Extra Pale Ale (bottled)

90 minute IPA with extra Malt (Mike's Batch)

Koelsch Ale (also Mike's)

Crazy Awesome Strong Stout (don't know what to call it yet - maybe Toothkicker)

and hopefully tomorrow:

Crazy Malty 30 minute big'n'sweet IPA

I hope to elaborate later

90 minute Extra Pale Ale (bottled)

90 minute IPA with extra Malt (Mike's Batch)

Koelsch Ale (also Mike's)

Crazy Awesome Strong Stout (don't know what to call it yet - maybe Toothkicker)

and hopefully tomorrow:

Crazy Malty 30 minute big'n'sweet IPA

I hope to elaborate later

Subscribe to:

Posts (Atom)